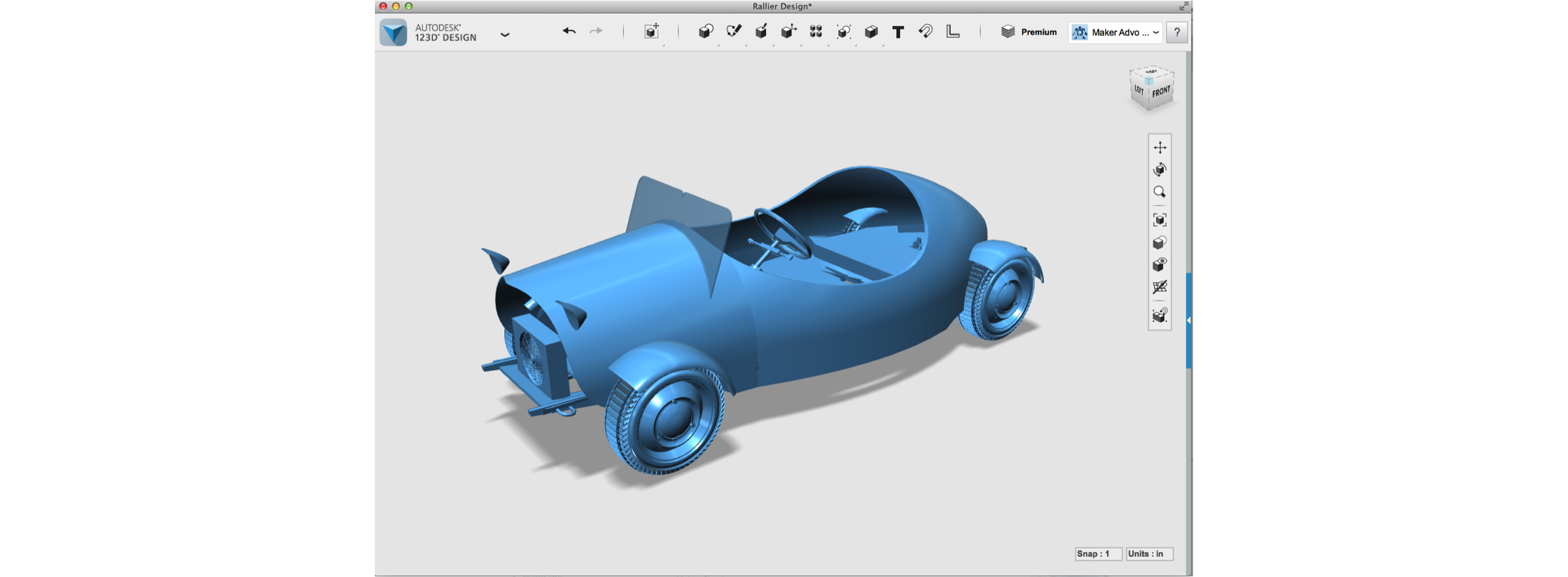

How to Make a Car Body with Autodesk 123D Make

Tony Luong Think of a Factory Five kit car as the ultimate adult Lego set. The premise: An average weekend warrior, armed with basic tools and about 250 hours of spare time, can build a hot rod,.

How to make a car body 3D Warehouse

Setting up the base for creating the plug to be carved to the eventual body shape.Follow along for the entire process of creating a carbon body for my car, a.

Yes, the manual is the size of a phone book. Yes it takes hundred of hours. But assembling your

In this video we are getting into detail on how I am building a body kit by using parts off of other cars. We are extending FC side skirts and modifying a To.

How to Make a Car Body with Autodesk 123D Make

Step 6. Begin laying your fiberglass. Start off with just one sheet soaked in resin, and lay it across the outside of the mold. Use a roller to push out any air bubbles, and tuck the fiberglass sheet around the edges and contours of your body kit. Allow the single sheet of fiberglass to completely dry, then gently pull it off of the foam mold.

3D printing 10th scale Shelby 1967part1/How to 3d print rc car body/Painting rc body/Scale

Bill demonstrates a new method he develops. Music: Technoaxe

How to Make a Car Body with Autodesk 123D Make

Chris Rünge builds made to order sports cars in his garage. He uses a technique called English Coachwork to bend aluminum panels into the classic curves that.

How to Make a Car Body with Autodesk 123D Make

This is a very easy way to make a body kit for your toy cars. this is NOT a permanent body kit that will always stick to your toy car - you can remove it - s.

How to Make a Homemade Car A StepbyStep Guide to Building Your Own Vehicle The Enlightened

1 Select the proportions of the car based on car's main purpose. Draw the rough shape of the car using straight lines and right angles instead of curves. Then, divide this block-shaped car into 3 or 4 squares, with 1 on top and 2-3 on the bottom. Finally, change the size and location of the squares to reflect how the car is intended to be used. [1]

How to Make a Car Body with Autodesk 123D Make

1. Carbon Quattro 2. Carbon Skyline If you think carbon fiber is cool, then you must think carbon fiber-bodied cars are even cooler. I found a couple of cars at the 2021 SEMA Show in Las Vegas, Nevada that used carbon fiber on their carbon fiber, so you can carbon while you fiber. Or something like that.

How to Make a Car Body with Autodesk 123D Make

Step 1: Car Body Design The body of the car is the main shape of the project. The body will tell us where the axles and wheels will be positioned, and it will have the balloon connector on it, so we will begin here. Let's get started! Instructions Place a box on the workplane and size it to be 20mm wide, 60mm long, and 20mm tall.

How to Make a Car Body with Autodesk 123D Make

Step 3. Cover the foam with body filler and let it sit for two hours to dry. Sand the filler with 220-grit sandpaper to remove any undulations and bumps. Spray three coats of polyester primer directly on top of the body filler and follow the on label directions for drying time. Once dry, use 220-grit sandpaper to smooth the surface of the primer.

Diy Auto Body Paint Stands

Step 1: 3D Wireframe Drawing From this 3D wireframe draw all the 2D parts for laser cutting. Step 2: Start from the first step : join the central longitudinal section (D) with the first two cross sections. Step 3: Add the inside longitudinal sections (B,C,E,F). Step 4: Add another cross section. Step 5: Add the outer longitudinal section A. Step 6:

How to Make a Car Body with Autodesk 123D Make

Step 4. Sandblast the entire body of the vehicle to scour the surface as clean as possible prior to painting. Apply your desired paint (and primer if necessary) and let it dry. Finish detailing the car and add any logos, custom hand-painted designs or otherwise. Building custom cars is a hobby that has grown over the years into a worldwide.

How to Make a Car Body with Autodesk 123D Make

The remarkable point is how thin the wall thickness is on 1 inch square tubing. Take a saw and cut through the frame tube. Then cut through the body skin. Yep!! It's a lot thinner than body skin! In addition the way the tubes lay on top of each other provide a massively stronger connection than A fish mouth joint on round tube frames.

fiberglass race car bodies Jettie Metzger

One way to make sure a replacement 1/10 scale RC body will fit your RC car or truck is to buy another of the same body that was originally included with it in the box. Your car's instruction manual should include an exploded view diagram, parts listing, or both. Check there for the part number of the direct replacement 1/10 scale RC body to.

Build Your Own Car

Designing a car body doesn't mean going overboard in the field of fantasy and creating a Buck Rogers spectacle designed to confuse the befuddled public as to the true purpose in life, unless that's the direction in which your tastes jet. You'll have just as much fun, and a good deal more success if you stick closer to the more.